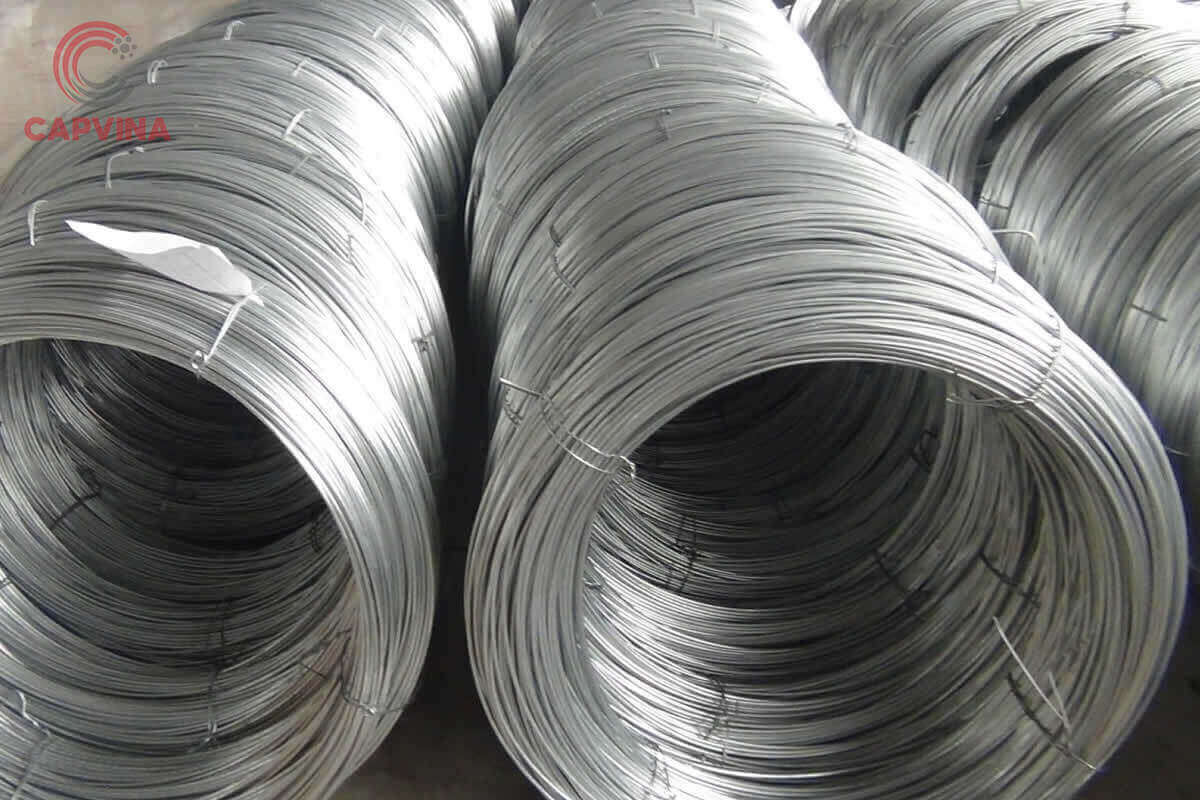

Galvanized steel wire cable is a type of cable galvanized by hot-dip method, with high carbon content, so it has extremely good rust resistance and is used a lot in today’s life. You are interested and want to buy galvanized steel cable for your project or other needs but don’t know where to buy it? Refer to the following post with CAPVINA Company!

What Is a Galvanized Steel Wire Cable?

Galvanized steel wire cable is crafted from high-quality carbon steel and undergoes galvanization through the hot-dip method. This type of steel cable serves various purposes, including lashing, anchoring, and pulling equipment where extremely high load-bearing forces are not necessary. It finds application in diverse scenarios such as scaffolding, roof bracing, pillar anchors, protective nets, safety nets, anti-fall nets, and more.

Features

The cable is manufactured from steel material with a high percentage of carbon and is braided from large strands of cable in a defined direction, making the cable durable and not easy to unravel. The surface of the cable is galvanized using the hot-dip method to prevent rust extremely well, so it can be used in many different weather conditions.

The small cables in the cable strand are made from high quality carbon steel, cold drawn, then tightly braided. Then it is galvanized by hot-dip method, creating a nice even layer of zinc on the cable. Thanks to this zinc plating layer, the cable has a beautiful metallic shine and is very resistant to abrasion and rust.

Specification of galvanized steel wire cable

The basic technical parameters of current high-quality galvanized steel cables are as follows:

- Specifications: 6×12+7FC, 6×19+FC, 6×37+FC…

- Origin: China, Korea…

- Safe pulling force: > 1700 N/mm2

- Safety factor: 1460 N/mm2.

- Diameter: 3mm, 4mm, 5.5mm, 7.5mm, 8.5mm, 9.3mm, 11mm, 13mm, 15mm, 17mm, etc. Each cable diameter will have different bearing capacity and based on usage needs. that one will use the appropriate cable type.

- Packaging: 1,000m/roll. The cable is tightly wound onto the wooden drum, convenient for transportation, easy use and safe installation.

Hot-Dip Galvanizing Process

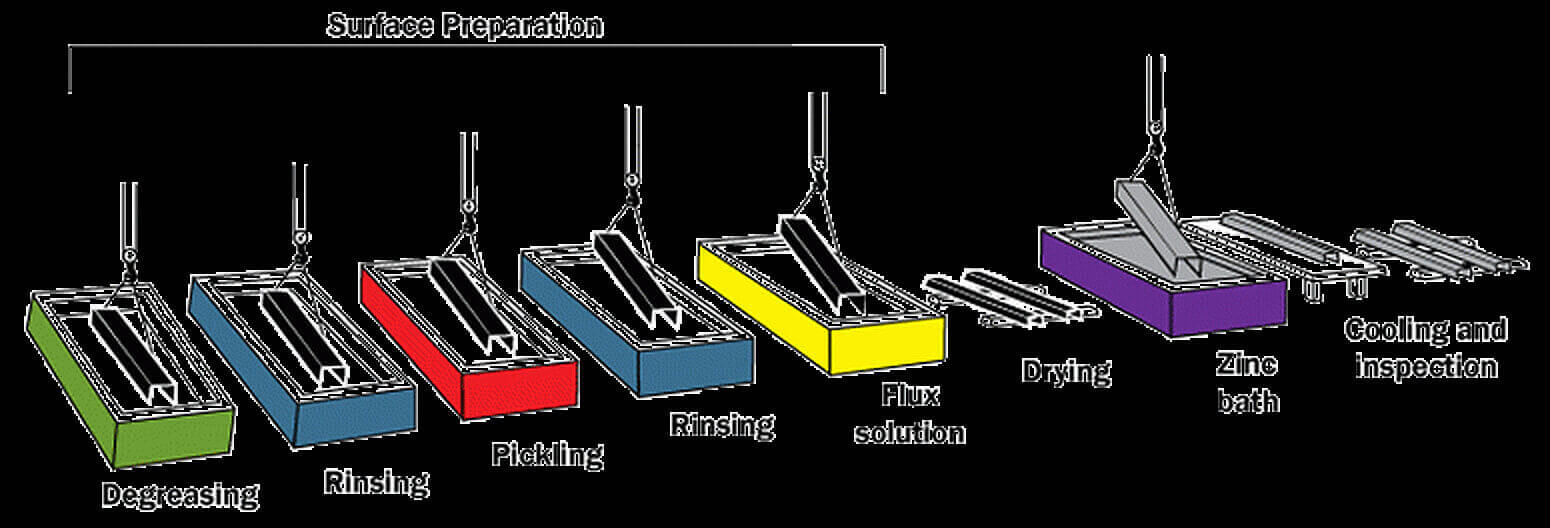

Prior to delving into the intricacies of designing for hot-dip galvanizing, it is imperative to comprehend the fundamental steps of the galvanizing process: surface preparation, galvanizing, and inspection.

Surface Preparation

The surface preparation stage within the galvanizing process possesses inherent quality control mechanisms, as zinc does not readily react with unclean steel. Any deficiencies or shortcomings in the surface preparation will become readily evident upon removing the steel from the zinc bath, as the unclean regions will remain uncoated. Consequently, prompt corrective measures can be implemented.

Degreasing

An alkaline solution heated to high temperatures, a mildly acidic bath, or a bath specifically designed for biological cleaning are effective methods for eliminating organic impurities, including dirt, paint marks, grease, and oil, from the surface of metal. However, substances such as epoxies, vinyls, asphalt, or welding slag, which cannot be eliminated through degreasing, must be removed prior to the galvanization process using techniques such as grit-blasting, sand-blasting, or other mechanical means.

Pickling

A diluted solution of heated sulfuric acid or ambient hydrochloric acid is employed to eliminate mill scale and iron oxides (rust) from the surface of the steel. In addition to pickling, this process can also be achieved by utilizing abrasive cleaning or air blasting techniques, such as sand, metallic shot, or grit, on the steel surface.

Fluxing

The ultimate step in surface preparation, involving the utilization of a zinc ammonium chloride solution, serves dual objectives. Firstly, it eradicates any residual oxides present on the steel surface. Secondly, it applies a safeguarding layer onto the steel, thereby impeding the formation of additional oxides upon immersion in the molten zinc.

Galvanizing

The process of galvanization involves the complete immersion of steel in a bath of molten zinc, which is considered the “galvanizing” step. The bath chemistry must adhere to a specification of at least 98% pure zinc and must be maintained at a temperature of approximately 840 F (449 C). The discretion to add 2% of additives lies with the galvanizers, within certain limits. Common additives include aluminum, bismuth, and nickel, which aid in the fluidity of the zinc, controlling coating thickness, and appearance.

During immersion in the kettle, the iron in the steel reacts with the molten zinc, resulting in the formation of a series of intermetallic (zinc/iron) alloy layers. The galvanized coating becomes an integral part of the steel, rather than a surface coating, as the metallurgically-bonded layers of the coating are tightly connected at approximately 3,600psi. The steel remains in the bath until it reaches bath temperature and is then slowly withdrawn at an angle from the galvanizing bath. Excess zinc is removed through draining, vibrating, and/or centrifuging (spinning).

The metallurgical reaction continues after the material is removed from the bath, as long as the article remains near bath temperature. Articles are cooled either by immersion in a passivation solution or water or by being left in open air.

Inspection

Check that all cables are coated with zinc, then cool with cold air or water. Finally, the technician will thoroughly check the standards ASTM, AS/NZS,… before delivering to the customer.

Advantages of Galvanized steel wire cable

- The service life of this product is superior to that of electro galvanization. It entails the formation of an iron-zinc alloy layer on the steel surface, as well as a pure zinc coating on the outer surface.

- The resulting alloy is characterized by exceptional hardness and resistance to common forms of abrasion.

- Additionally, the coating thickness can be up to ten times greater than that of electro galvanization.

Applications

Due to its enhanced corrosion resistance in comparison to electro galvanized cable, hot dip galvanized cable is suitable for various applications where the cable will be exposed to natural elements or a caustic environment. It can be utilized for fencing or perimeters in construction sites, parking garages, farm and livestock facilities, and numerous other settings.

Moreover, Galvanized steel wire cable is well-suited for lifting and rigging in crane applications, as well as for outdoor winches or pulley systems. It is also commonly employed in professional zip lines, as it can withstand corrosion in moist and humid environments.

Buy hot-dip galvanized steel cable at CAPVINA

Following this, you are surely very interested in hot-dip galvanized steel cable products, and are looking to buy this item? Vietnam Bao Bap Company will be a great choice for you.

High quality Galvanized steel wire cable distributed at our Company are all products manufactured and imported directly from Korea and advanced countries around the world. All will be absolutely guaranteed in quality, the appearance will retain its long-lasting shine, be galvanized by hot-dip method so it does not rust, good durability in many different environmental conditions and the ability to have extremely high strength.

If you are still worried about hot dip galvanized steel cable price with fluctuations in the steel market and changing policies that are difficult to calculate, then rest assured, Vietnam Steel Cable will bring you the most competitive prices of products, depending on your needs.

Pick up the phone and contact us immediately via hotline 0901 577 139 (Mr. Phat) for a quick and detailed quote!

Reviews

There are no reviews yet.