Anchor chains are a vital element in the maritime industry, serving a pivotal role in securing ships and other sizable vessels. Constructed from durable steel, these chains are specifically engineered to withstand the challenging conditions of the marine environment. This article will delve into the various classifications of anchor chains, the materials used in their production, and provide valuable insights on effective maintenance.

What are anchor chains?

Anchor chains are chains specifically designed for the purpose of anchoring vessels. These chains are connected to the vessel’s anchor on one end and to the seabed on the other end. Typically, these chains are constructed by welding together multiple links, resulting in a robust and long-lasting chain.

Structure

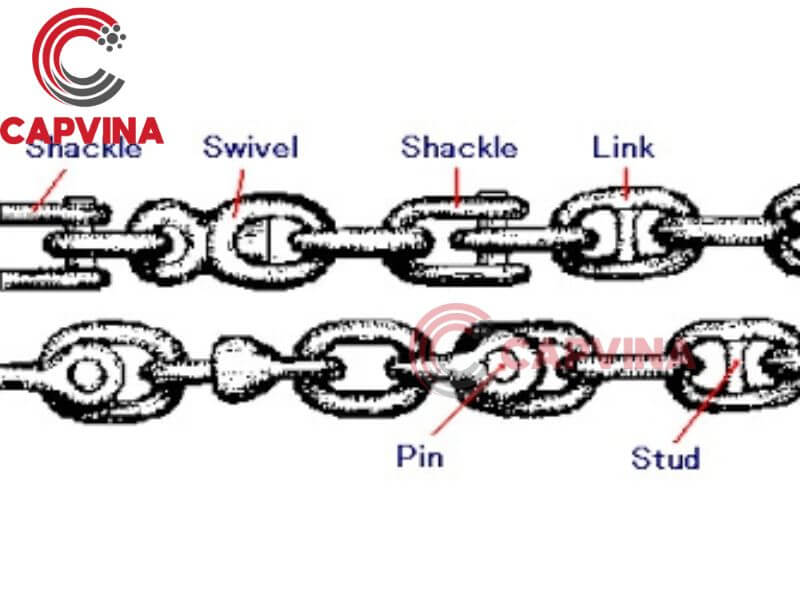

A shackle is a load-bearing connecting device that has a u-shaped design and is intended for use with a removable pin. It is versatile and can be utilized in various riggings and load-securing arrangements to connect different types of lifting slings, chains, or ropes to an object or to one another.

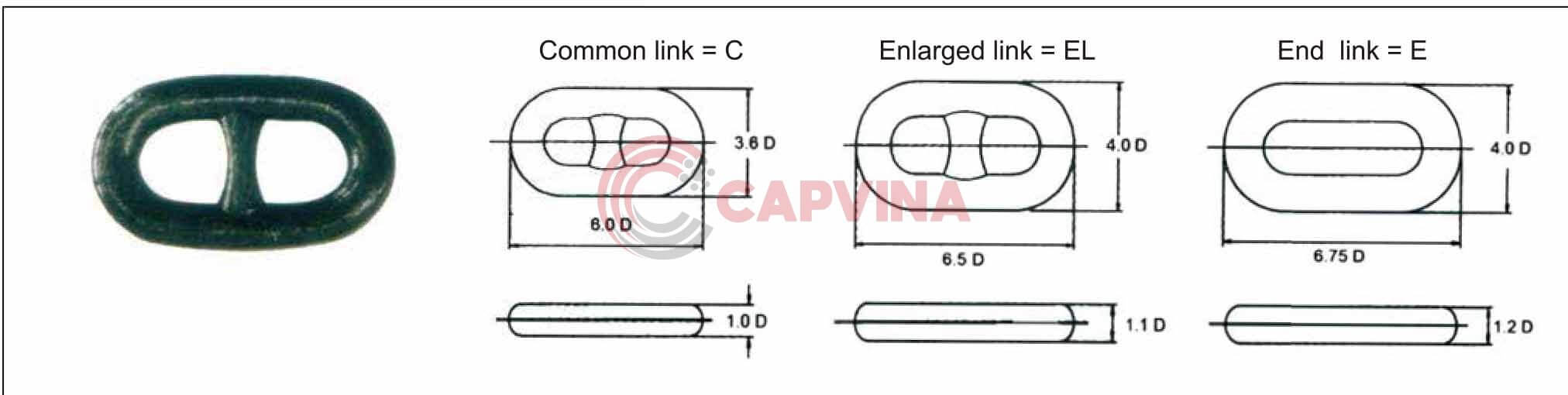

In this step, we will discuss the connection between the Anchor and the anchor chain. This connection is established using shackles and other components:

- Anchor Shackle

- End Link

- Enlarged Link

- Swivel

- Common Links

- Kenter Shackle

Specification

What are the different types of anchor chains?

There are various anchor chains available in the market that can be categorized based on their size, material, and strength. Here are some commonly utilized anchor chains:

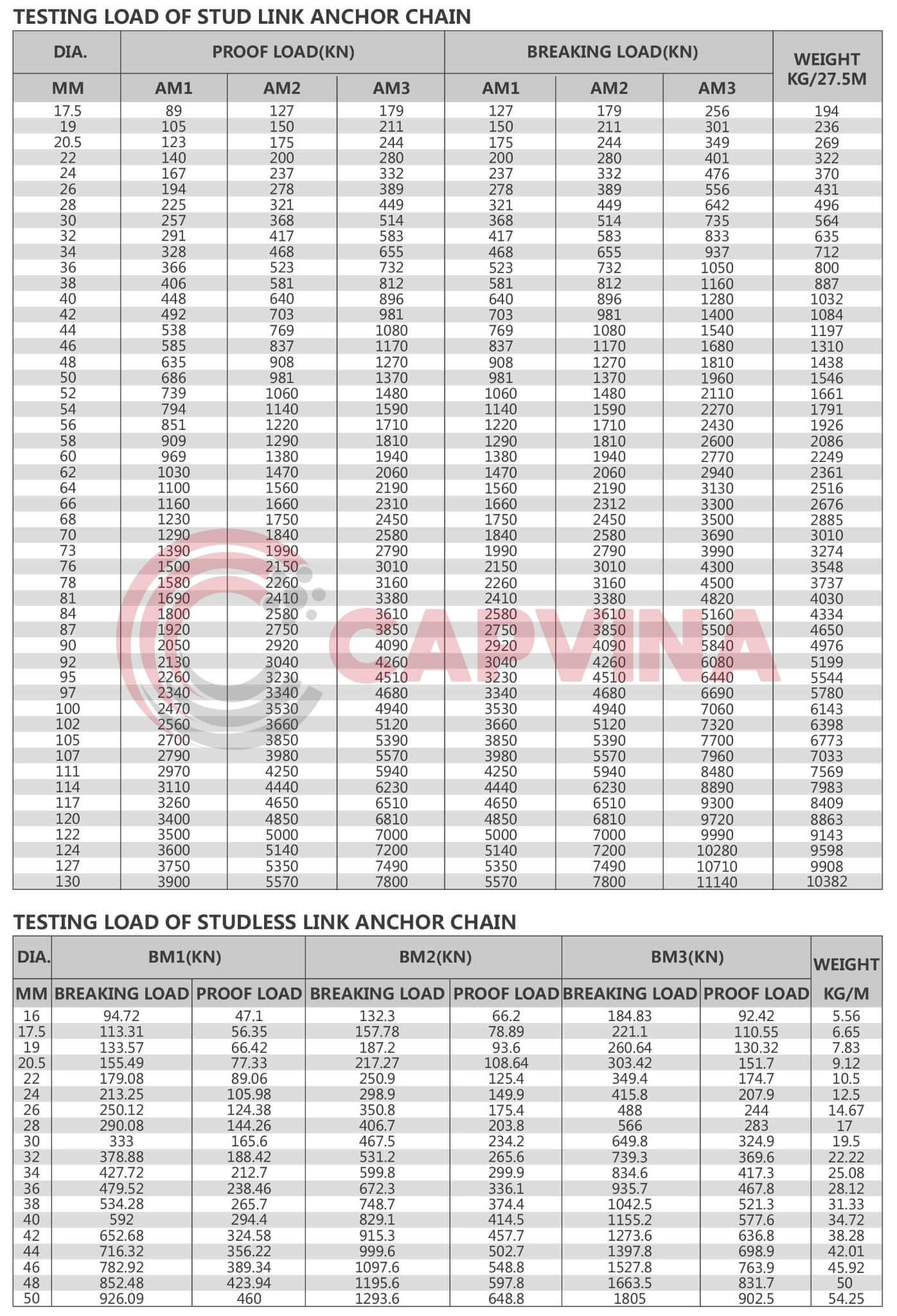

- Stud Link Anchor Chain: This type of anchor chain is widely used and features studs or projections on its links, preventing any twisting of the chain.

- Studless Anchor Chain: In contrast, the studless anchor chain is lighter and more flexible than the stud link anchor chain, enabling it to lie flatter on the seabed.

- Anchor Chain Grades: They are available in different grades, which determine their strength and durability. The commonly used grades include Grade 2, Grade 3, and Grade 4.

- Galvanized Anchor Chain: Galvanized anchor chains are coated with a layer of zinc, providing additional protection against corrosion.

How are anchor chains made?

Anchor chains, composed of high-strength steel, exhibit resistance to both corrosion and abrasion. To enhance their strength and durability, the steel is commonly alloyed with metals like manganese, chromium, and nickel. The manufacturing of these chains involves a combination of heat treatment, forging, and welding techniques.

Importance of anchor chains

Using a chain facilitates a faster and more reliable anchor setting by applying a downward force to the anchor handle, commonly referred to as the shank.

Using the breakaway release method reduces the chances of losing an anchor that might be trapped beneath an object.

Prevents damage to your nylon line, which can be caused by underwater debris or sharp objects, potentially leading to a cut line and the loss of an anchor.

Energy is transferred to the anchor handle’s end in a downward direction. You can think of it as if you were extending the handle by 4 feet when adding 4 feet of chain to the anchor. While having such a long handle isn’t practical, you can imagine the leverage it would offer.

Maintain tips

To ensure the longevity and effectiveness of chains, it is imperative to maintain them properly. Regular inspections must be conducted to detect any signs of wear and tear or deformation. Additionally, cleaning the chains on a routine basis can aid in preventing corrosion and extending their lifespan.

Here are some helpful tips:

- After each use, it is important to rinse your chain with freshwater to eliminate salt and avoid rust. It is crucial to regularly check your anchor chain for any indications of wear and tear, such as bent or broken links, and promptly replace any damaged links.

- To prevent corrosion and rust, it is recommended to lubricate your anchor chain with corrosion-resistant grease.

- Furthermore, storing your anchor chain in a dry and well-ventilated area will help prevent corrosion.

- Before embarking on a voyage, it is essential to thoroughly inspect your anchor chain and ensure that it is in optimal working condition.

Understanding the various types of anchor chains and their proper maintenance is crucial in ensuring a safe and efficient maritime operation. They play a vital role in the maritime industry as they provide a secure and reliable method of anchoring large vessels in a specific location. By familiarizing oneself with the different types of anchor chains and learning how to properly maintain them, maritime professionals can enhance the safety and effectiveness of their operations.

CAPVINA Wire Rope Company

CAPVINA Wire Rope Company provides anchor chains and other types of them depending on the needs and purposes of customers: appropriate size and design.

With many years of experience in the field of supplying anchor bracing products, especially anchor chains for all types of boats nationwide. CAPVINA Wire Rope Company is confident in being a reputable and high-quality distributor of anchor chains and other types of ship anchors.

To purchase suitable anchor chains, customers can contact directly at:

- Address: 18/13 Vinh Phu 26, Trung Quarter, Vinh Phu Ward, Thuan An City, Binh Duong Province, Viet Nam

- Mail: baogiacapthep79@gmail.com

- Hotline: 0901.577.139

Reviews

There are no reviews yet.