Anchor shackles are a series of mechanical products used to connect chain cables and crane hooks to shipments, rolls, containers, and more in factories, plants, construction sites, and wharves, or for lifting, transporting, or anchoring work. The following article will provide more specific information about anchor shackles for readers to reference.

What is the Anchor Shackle?

Anchor shackles are products created through a monolithic forging process, with the primary raw material being high-strength carbon steel. All steps of the production process must undergo rigorous inspection, from the selection of input materials to the final output. This ensures that the breaking force of the shackle is at least six times greater, and the load-bearing capacity is at least twice the design specifications allow.

A shackle consists of two main components: the body and the screw. The shackle body is designed in a U or omega shape and is cast from tempered carbon steel. The surface is plated to meet EC standards. The fasteners are made of galvanized alloy steel or painted in standard colors, and they include a threaded screw and a safety latch for use.

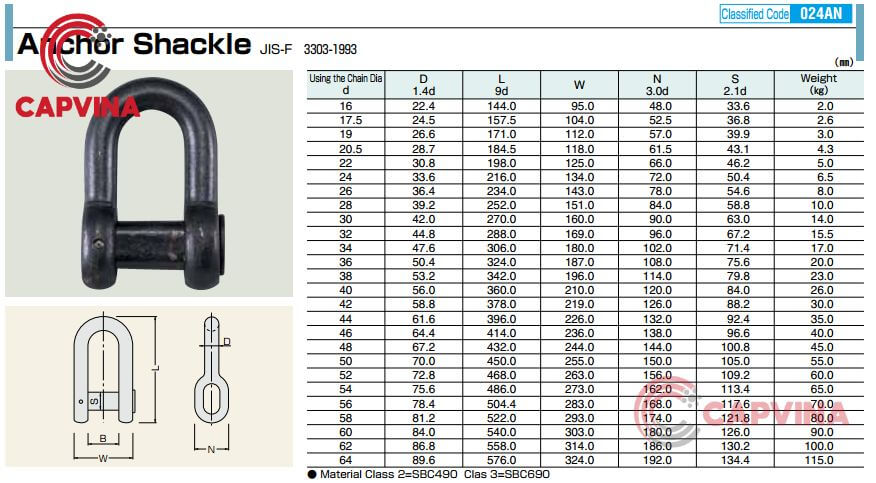

Specification

What is Anchor Shackles for?

Depending on different uses, consumers choose anchors with load capacity, shape, origin, etc. that best suit the job and save costs:

- Accessories for steel cable slings, chain slings, fabric straps… in lifting and lowering goods at warehouses, seaports, or heavy objects in construction projects.

- Support in anchoring, bracing, pulling electric poles, antenna poles, fences…

- Used to hook onto cranes, hoists, pillars, steel pipes…

- Used in applications related to load cases for trucks or boats.

Considerations for choosing the Anchor Shackle

When selecting an anchor shackle, it is important to take into account various factors, including the intended application, the maximum load capacity required, the type of materials being connected, and any specific safety standards that need to be met.

- Working Load Limit (WLL) and Safety Factor: To determine the necessary maximum load capacity for your specific application, it’s essential to ensure that the Working Load Limit (WLL) of the shackle exceeds this value. Consider the safety factor, which accounts for increased stress and dynamic loads.

- Material Selection Based on Environmental variables: When choosing a material for the shackle, it’s important to consider its exposure to environmental factors like moisture, temperature fluctuations, and chemical substances. It’s crucial to select a material that offers both resistance and durability to withstand these conditions.

- Application-Specific rules and Regulations: Consider any industry or application-specific rules or regulations, as certain industries, such as offshore and construction, may have stringent requirements concerning equipment and safety.

Maintenance and Inspection of Anchor Shackles

Regular maintenance and inspections are essential to ensure the optimal performance and safety of anchor shackles. Some key practices include:

- Conducting regular visual inspections to check for damage, distortion, or wear. It’s important to examine the shackles for cracks, bends, or elongation that could compromise their integrity.

- To ensure smooth operation, clean and lubricate the shackle’s moving parts, such as the pin. Regular cleaning is also necessary to remove dirt, debris, or corrosive substances that could hinder their operation.

- Proper storage and handling are essential. Keep the shackles in a clean, dry environment to prevent corrosion. Additionally, handle them with caution, avoiding any impacts or drops that could cause damage

CAPVINA Wire Rope Company with anchor shackles

Anchor shackles are in high demand across various industries in our country. Due to their significance and the importance of safety, choosing reliable suppliers is paramount.

CAPVINA Wire Rope Company is a trusted provider of anchor shackles that meet international quality standards in the Vietnamese market. Our partners and customers consistently express satisfaction with the quality and pricing of our products.

All our anchor products are imported as complete units from renowned countries like Korea, Japan, and America. This ensures high quality, durability, and safety during use.

For further information, please contact:

CAPVINA WIRE ROPE COMPANY

- Address: 32 Street No. 40, Van Phuc Urban Area, Hiep Binh Chanh Ward, City. Thu Duc

- Hotline: 0901 577 139

- Email quotation: baogiacapthep79@gmail.com

Reviews

There are no reviews yet.